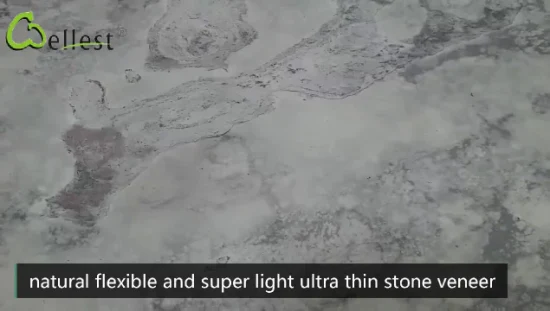

Through Color Fiber Cement Board Curtain Wall Cladding Similar with Equitone

1.It is d urable More than 60% of the composition is same as grantie, more than 20% same as marble. 2.High strength The

Basic Info

| Model NO. | fiber cement board |

| HS Code | 68118200 |

| Production Capacity | 20000 Pieces Per Day |

Product Description

1.It is durable

More than 60% of the composition is same as grantie, more than 20% same as marble.

2.High strength

The lowest strength(in parallel)is≥15Mpa.While the higheat strenth(in cross)is≥20Mpa

which meets the National anti-typhoon requirement comppetely.

3.Light weight. Low water absorption.

The density is more than 1.4g/cm³.

4.Oustanding sound insulation capability for indoor partition and ceiling even the building

which has a strict demand in private.

5.Incombustible material

Meeting the standard of GB8624-1997 grade A1,ISO-1182 and BS 476 from UK which is the guarantee of fire proof.

6.Good at impact resistant

It can be used as the base board in the shops, hotels, schools, entertainment places and hospitals.

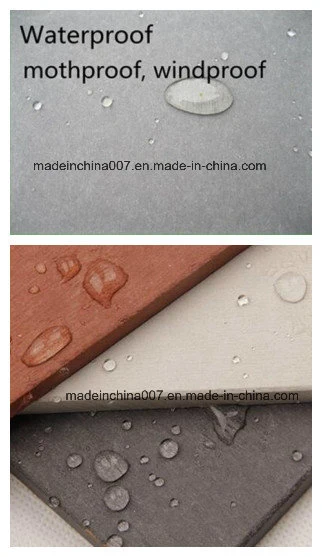

7.Low moisture absorption

It can be used in both outdoor and indoor for washing room and kitchen.

8.Non-radioactivity

All of our prodcuts including Cladboard meet the national standard and there are all allowed to be

used in any place of civil building to ensure the security of user.

9.Inorganic material

It's fire proof, anti fungus and antiseptic which is good for the health of user.

10.It can be use in many kinds of building,because it has the capability of anti-chemical corrosive.

11.Easy to install

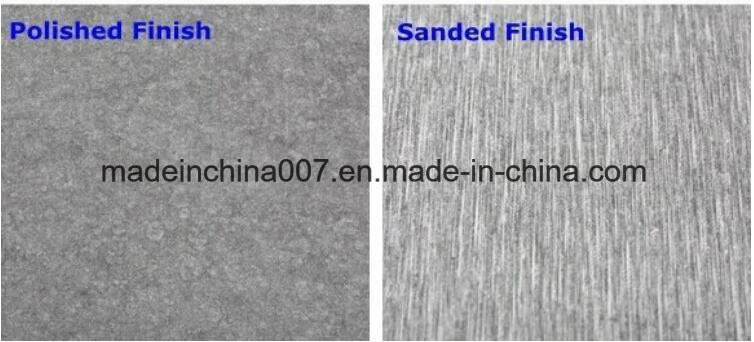

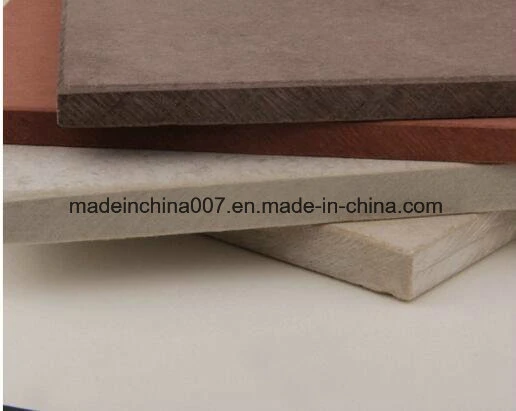

1.Specification

| Thickness | Width | Length |

| 5mm-20mm | 1220mm | 2440,3050mm |

| REMARK: We can also supply other specification as the client's specially requirement | ||

2.Tolerance in dimension

| Item | Requirement | |

| Length(mm) | <1200 | ±3 |

| 1200~2400 | ±4 | |

| >2400 | ±5 | |

| Width(mm) | ≤1200 | ±3 |

| >1200 | ±4 | |

| Thickness(mm) | ≤9 | ±0.3 |

| 9~15 | ±0.5 | |

| >15 | ±0.6 | |

3.Tolerance in shape

| Item | Requirement |

| Edge Straightness, mm/m | ≤2 |

| Squareness, mm/m | ≤3 |

| Surface Uneven, mm/m | ≤3 |

| Thickness Uneven, % | ≤6 |

4.Physical properties

The following data are the average tested figures during manufacturing

| Item | Index | Unit | |||

| Density | ≥1.40 | g/cm3 | |||

| Thermal Conductivity | ≤0.35 | W/(m·k) | |||

| Water Absorption | ≤28 | % | |||

| Water Contain | ≤10 | % | |||

| Moisture Movement | ≤0.25 | % | |||

| Freezing | No cracking or delaminating after 25 times of freeze-thaw cycles | ||||

| Non-water soaking | No Water Forms after being tested for 24 hours | ||||

| Non-combustibility | GB 8624 Class A | / | |||

| Bending Strength | Oven dry | Cross | ≥20.0 | Mpa | |

| Parallel | ≥15.0 | Mpa | |||

| Saturated | Cross | ≥15.0 | Mpa | ||

| Parallel | ≥10.0 | Mpa | |||

| Screwing withdraw | ≥110 | N/mm | |||

| Impact resistance | Oven dry | No Continuous Cracking After An Impact | / | ||

| REMARK: Please contact our technical department if you need more technical index. | |||||

Installation:

Production:

Package&Loading:

More information,please don't hesitate to contact us.

Send to us