Plastic Carpet Roll Flooring Wall Vinyl PVC Homogeneous Roll for School

Basic Info

| Model NO. | Homogeneous Flooring |

| Lead Hardness | Semi-Rigid |

| Surface Treatment | PUR UV Coating |

| Pattern | Floral |

| Color | Single Color |

| State | Coil |

| Usage | Commercial |

| Structure | Single Layer Top-to-Bottom |

| Transport Package | Wrapping Paper, Pallet, Container |

| Specification | 2.0m X 24m per roll |

| Trademark | SUMEC FLOORING, OEM Brand |

| Origin | China |

| HS Code | 391810 |

| Production Capacity | 400000sqm/Month |

Product Description

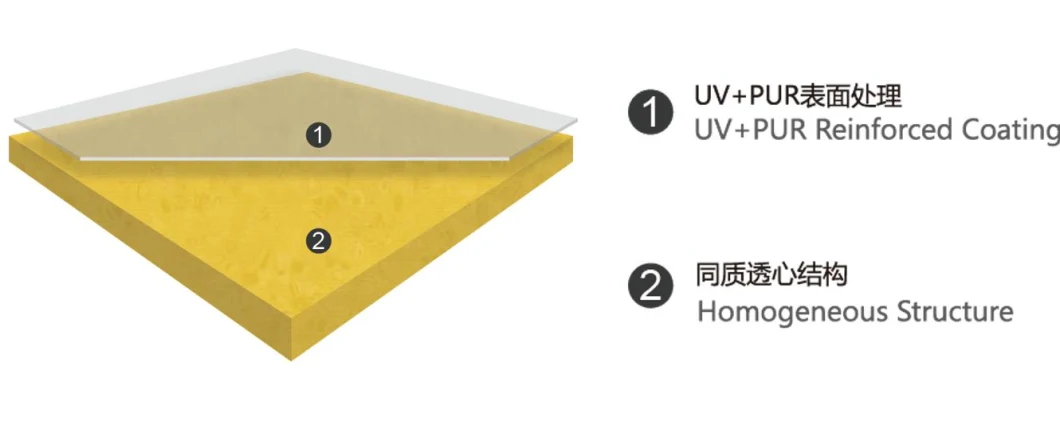

Product DescriptionHomogeneous Flooring Vinyl Roll, 100% Virgin Material, PUR + UV Coating - for school, college, university, youth center etc.

SUMEC Group was established in 1978, Nanjing, China, specialising in manufacturing and exporting. It's now listed in Shanghai Stock Exchange(Stock Code: 600710). SUMEC Flooring is the vinyl flooring business division. The products range includes SPC Plank, Luxury Vinyl Tile, Sports Flooring, Homogeneous Flooring, Heterogeneous Flooring, Non-slip Flooring, etc.

| Product | Homogeneous Flooring |

| Selling Points | Highly DurableChemical Resistance Coating |

| Warranty | 20 years |

| Material | PVC Resin, Plasticiser |

| Technic | Double Steel Belt Pressing,PUR + UV Coating |

| Structure | Single Layer Top-to-bottom |

| Footing | Semi-rigid |

| Package | Wrapping Paper |

| Roll Size | 2.0m X 24m |

| Thickness | 2.0mm, 3.0mm |

| Phthalates | NO |

| Heavy Metal | NO |

| Limit of Volatile Matter | Qualified |

| TEST ITEMS | TEST STANDARD | TEST RESULTS |

| Fire Classification | ISO 13501-1 | ClassBf1s1 |

| EN ISO 9239-1 | ≥8KW/m² | |

| EN ISO 11925-2 | Qualified | |

| Anti-slip Test | DIN 51130 | R9 |

| EN 13893 | µ≥0.3 | |

| Wear Resistance | EN 660-2 | Group T≤2.0mm³ |

| Dimensional Stability | ISO 23999 | ≤0.4% |

| Castor Chair Test | ISO 4918 | Qualified |

| Chemical Resistance | ISO 26987 | Qualified |

| Anti-bacterial Property | ISO 846 | No Bacteria |

| TVOC after 28 days | AgBB/DIBt | <10 µg/m³ |

Installation Instructions General Instructions1. On arrival at site, the rolls should be safely secured in an upright position2. The work area should be prepared to receive the sheet flooring. Check the condition of the subfloor and make good as necessary.3. Lay the sheet as directed. Fit the first length. Fit subsequent lengths.4. Align the decoration. Cut the seams.5. Use correct adhesive to adhere the sheet.6. Prepare skirtting profiles7. Fit ejecta capping strips. Fit sit-on capping strips. Fit the internal and external corners.

Other Products

FAQ

Q: How long is the lead time?

A: Normally, 10-15 days for flooring rolls; 25-35 days for SPC and LVT

Q: How long is the credit time?

A: Perhaps Usance L/C is the best solution. We only give credit to old clients

Q: How can I know the manufacturing progress.A: There will be a manager in charge. He/she will send you photos and videos

Q: Can I buy 10-20 sqm? 100-200 sqm?

A: Sorry, we do not retail

Q: Can I require some samples?

A: Of course. We can deliver to you. However, samples are in random dimension and colours

Q: Can you produce some samples in my specifications?

A: No, unless you need OEM products.